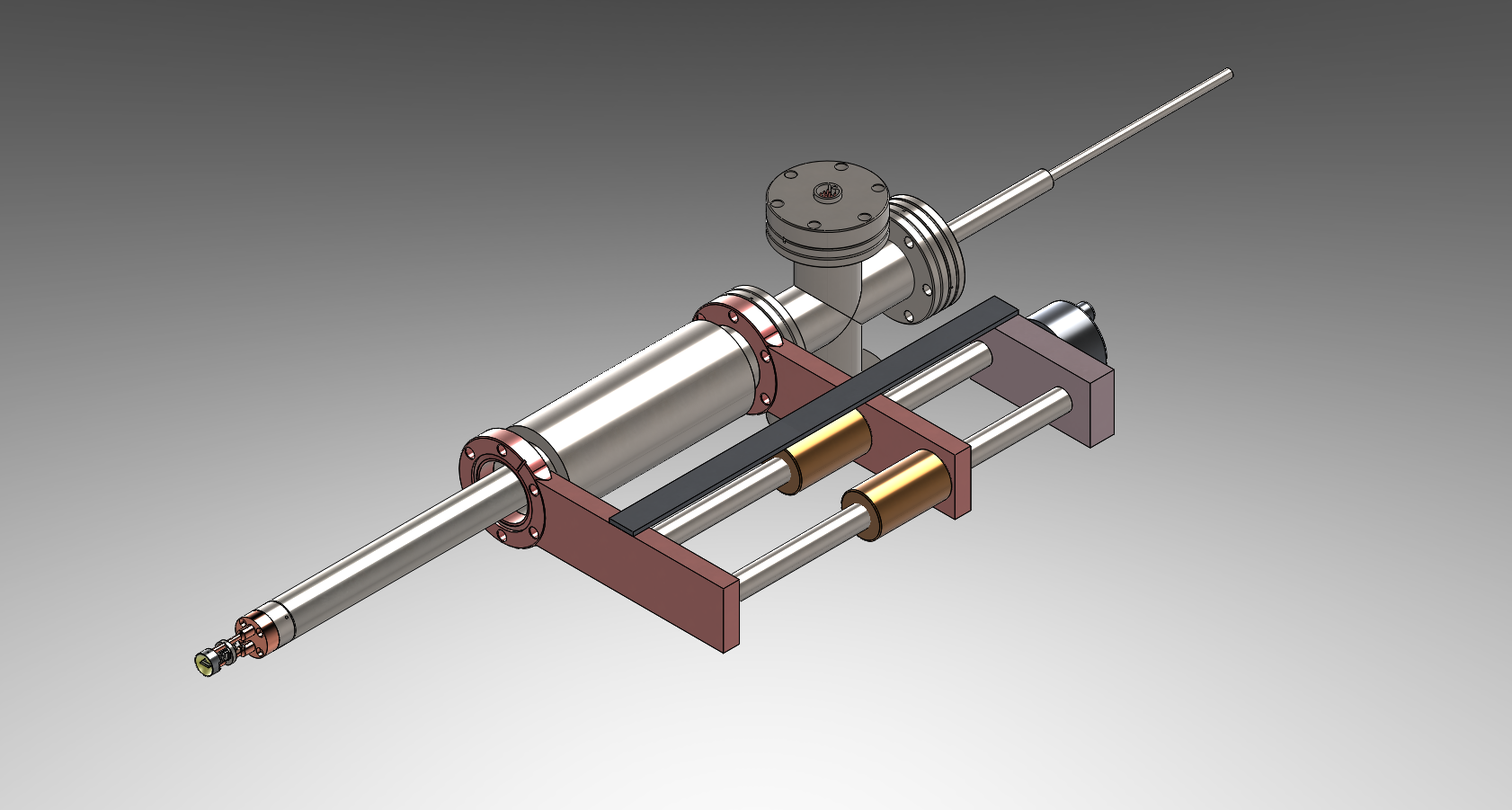

The Advanced Photon Injector Experiment (APEX) is a next generation electron gun designed to be the front end of superconducting accelerators and will produce well-formed pulses of electron bunches in the pico-second time scale.

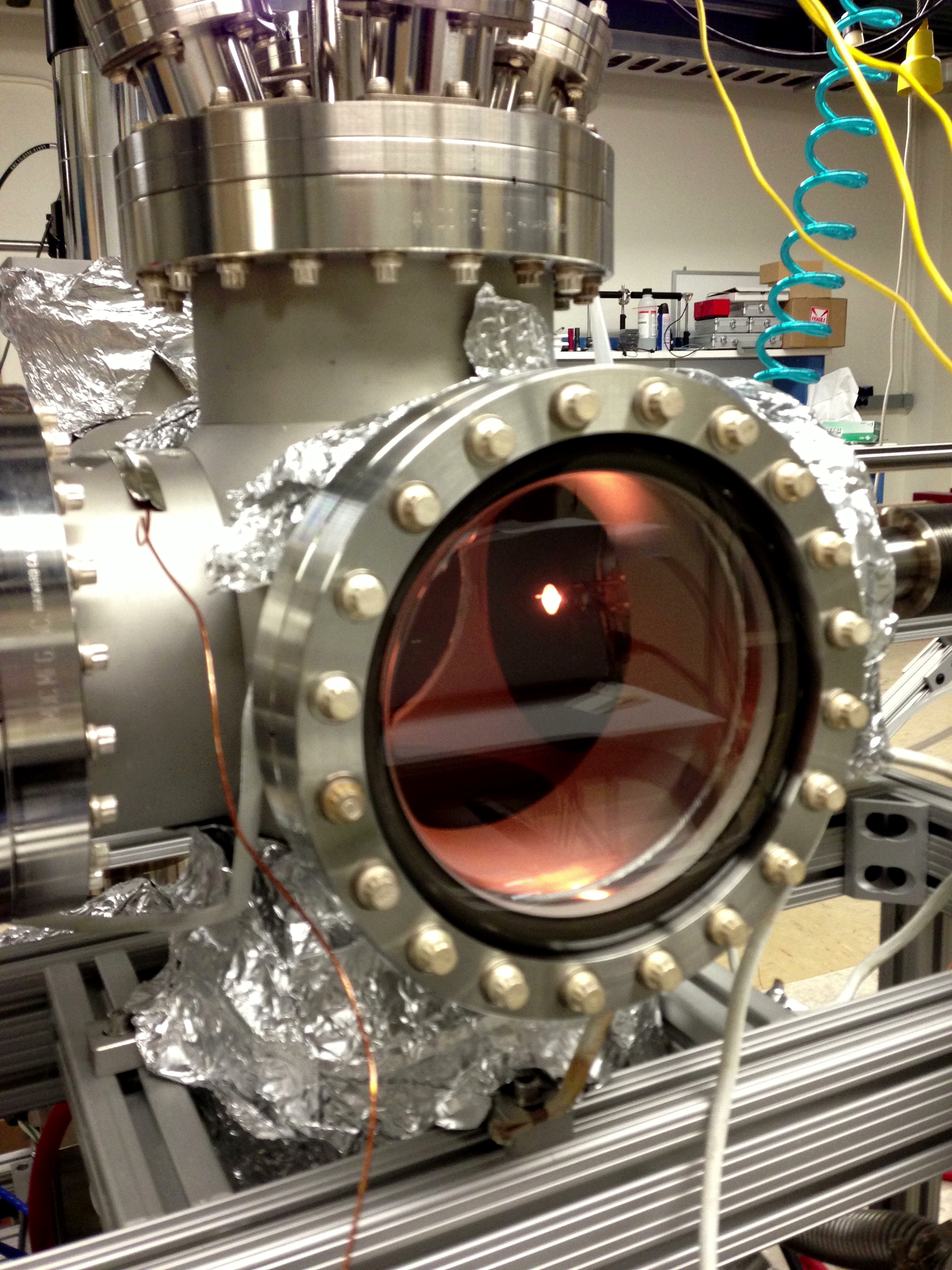

The deposition chamber is a separate system for determining the proper formulation of bi-Alkali (K2CsSb) photocathode materials and for evaluating different types of new photocathode materials (Topological Insulators etc...)

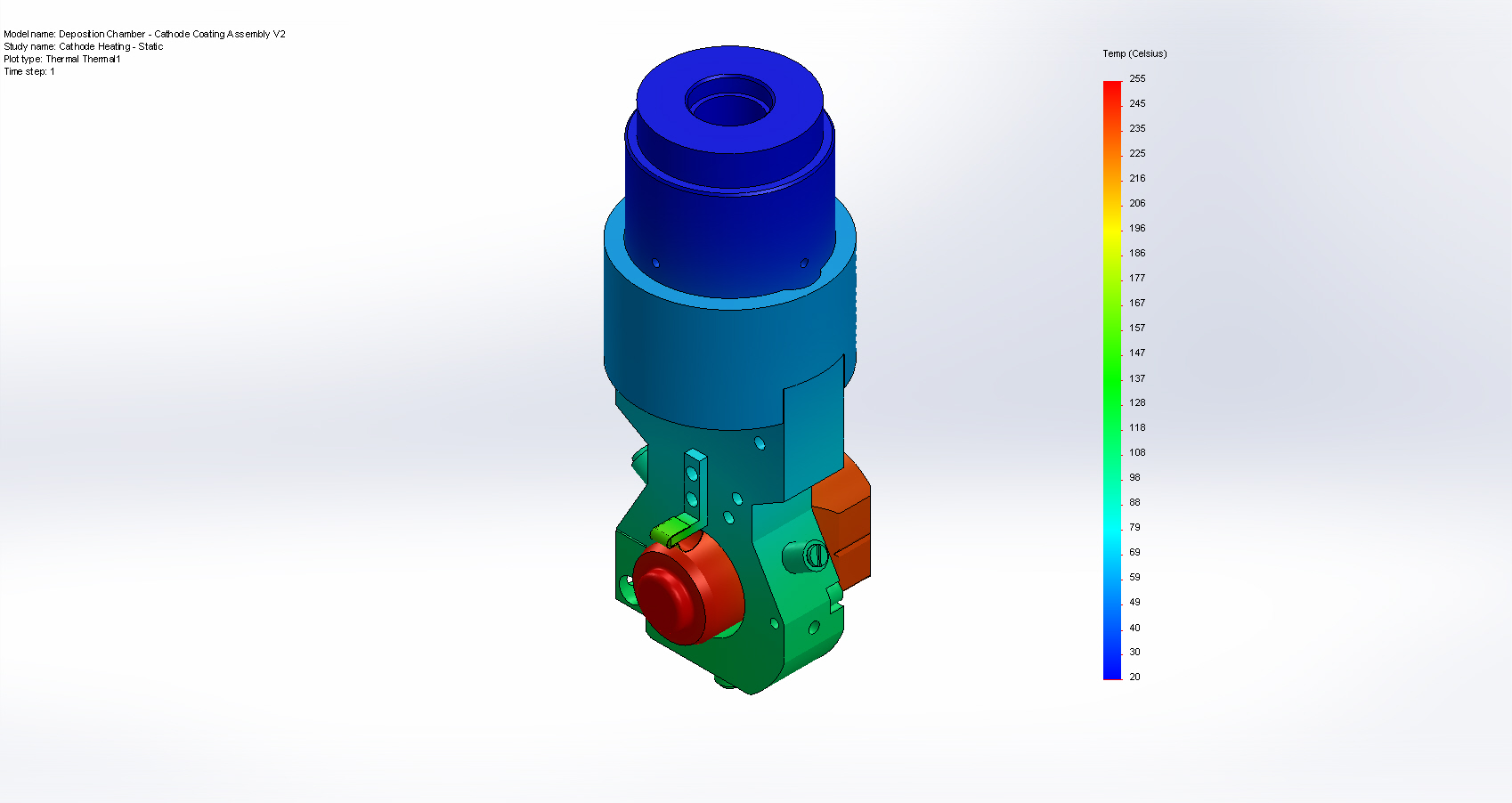

Before deposition, the cathode surface must first be cleaned by heating to 500C, and deposition is done at temperatures that range between 75 and 150C.

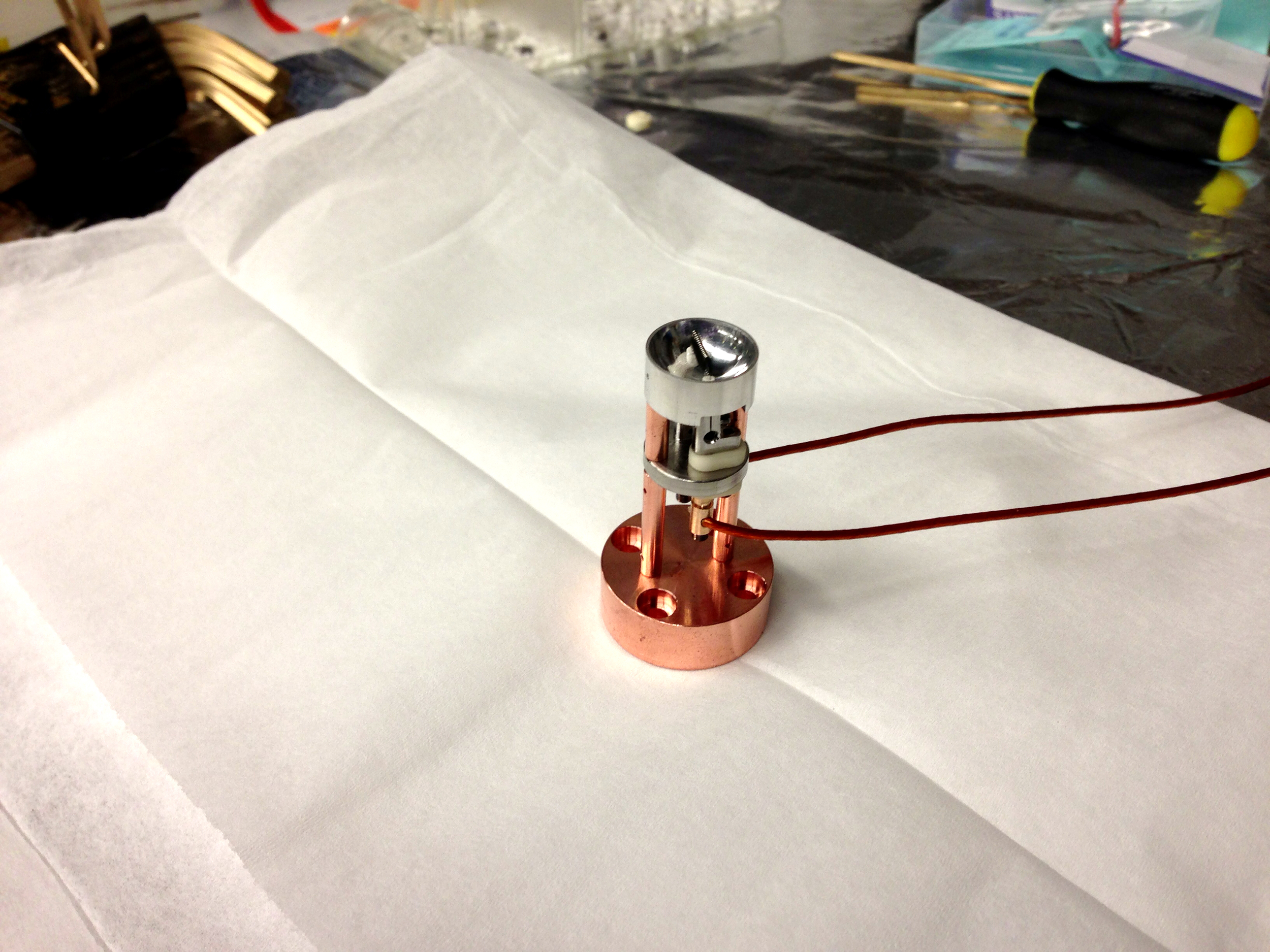

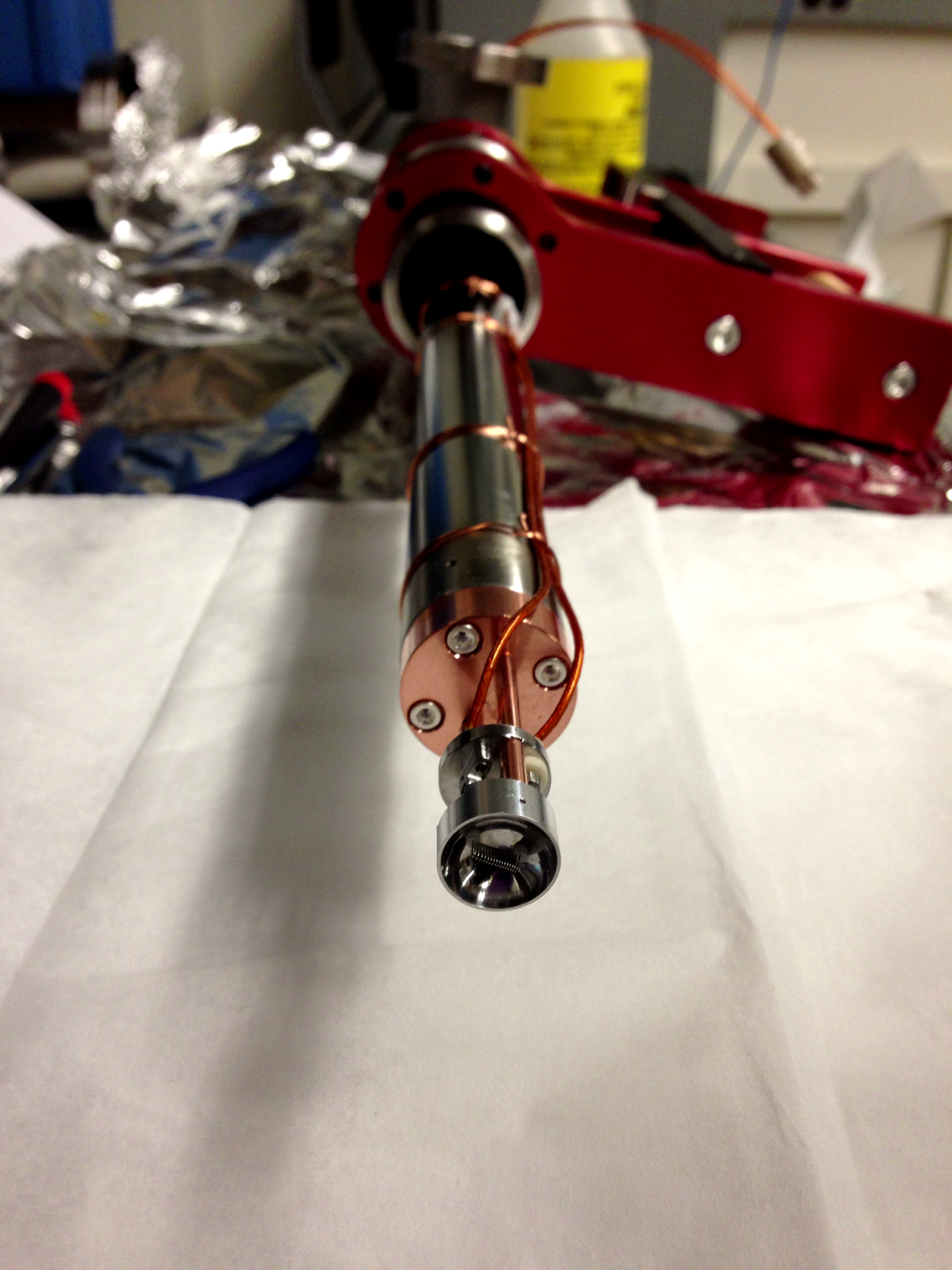

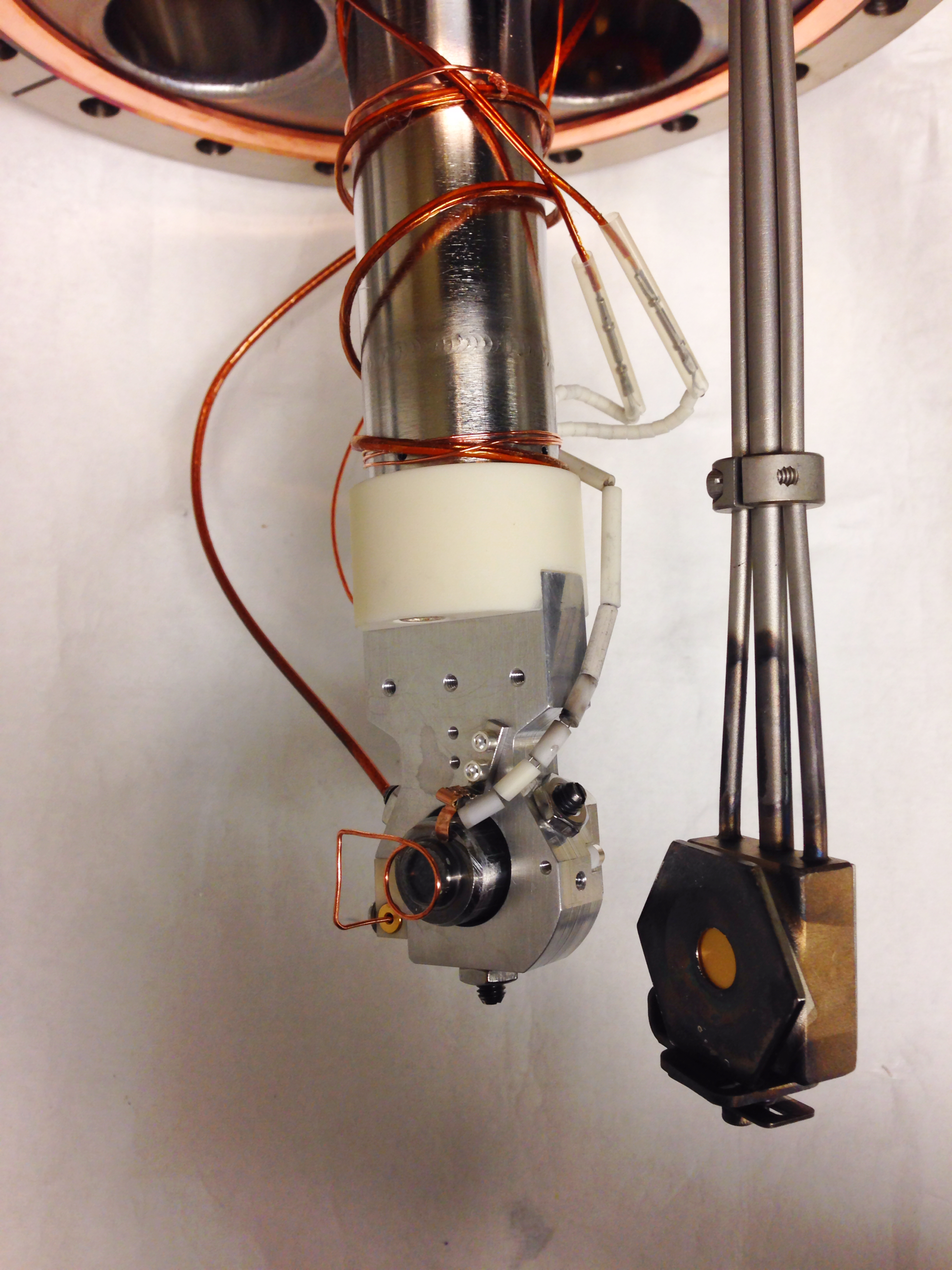

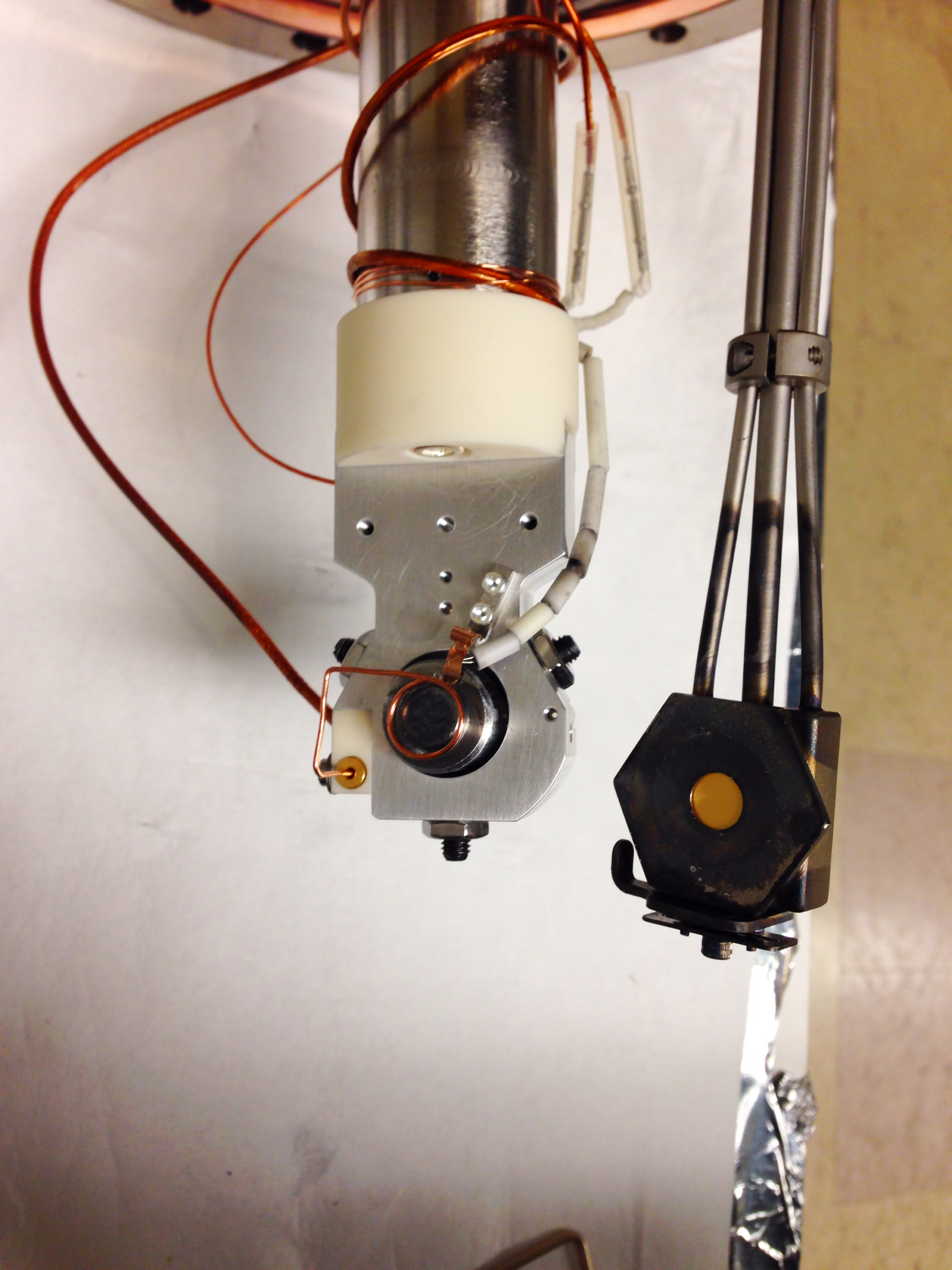

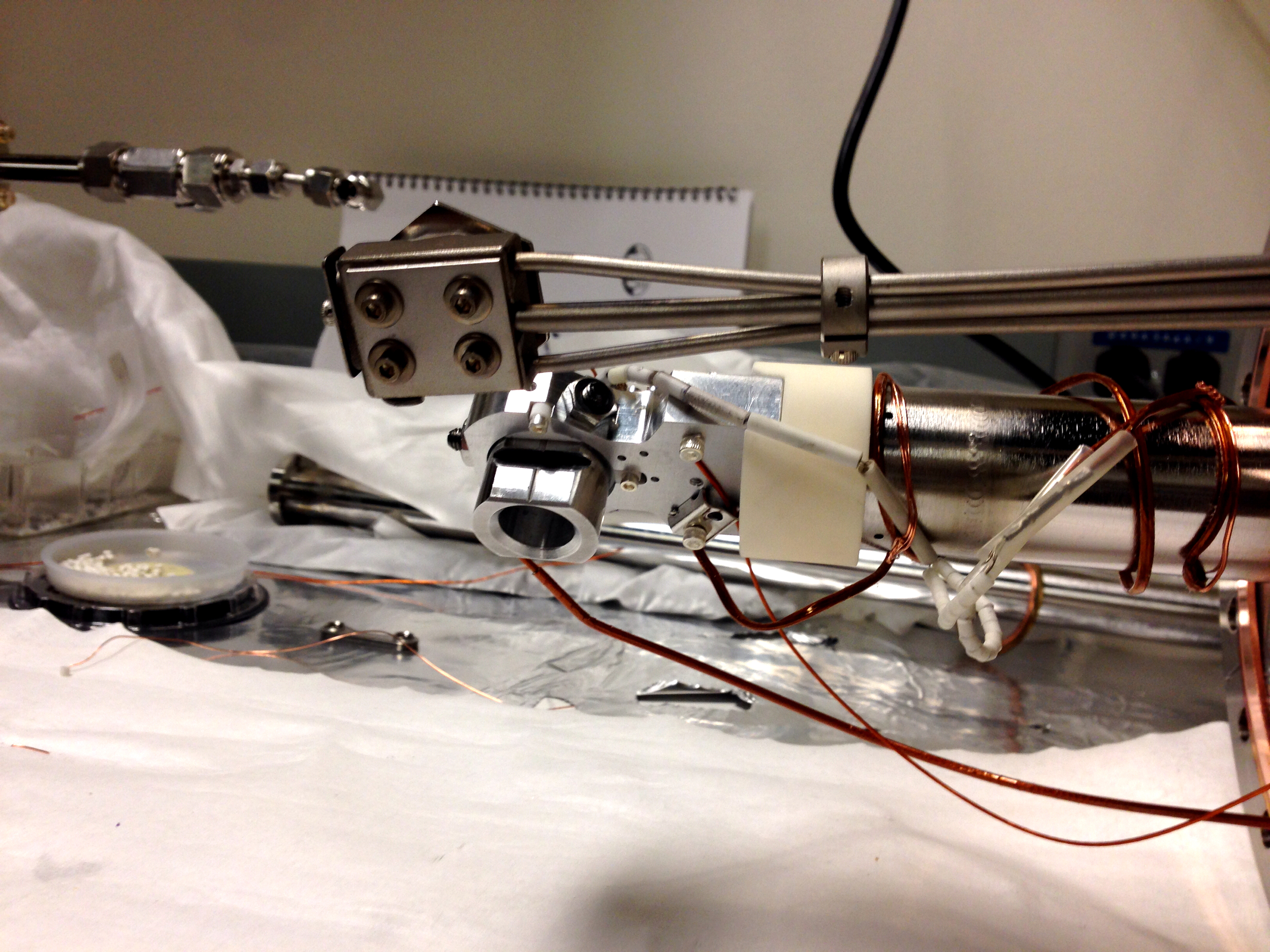

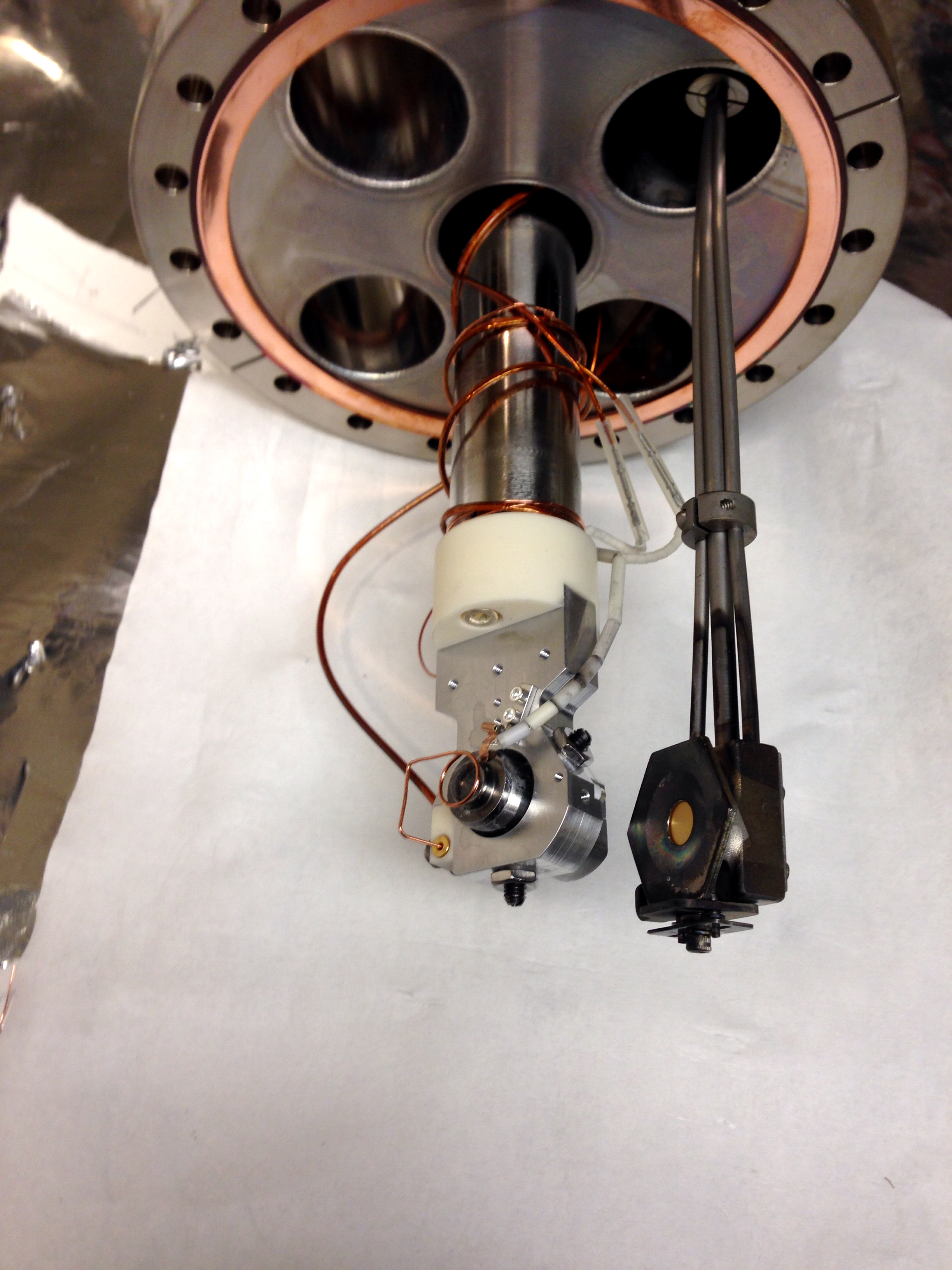

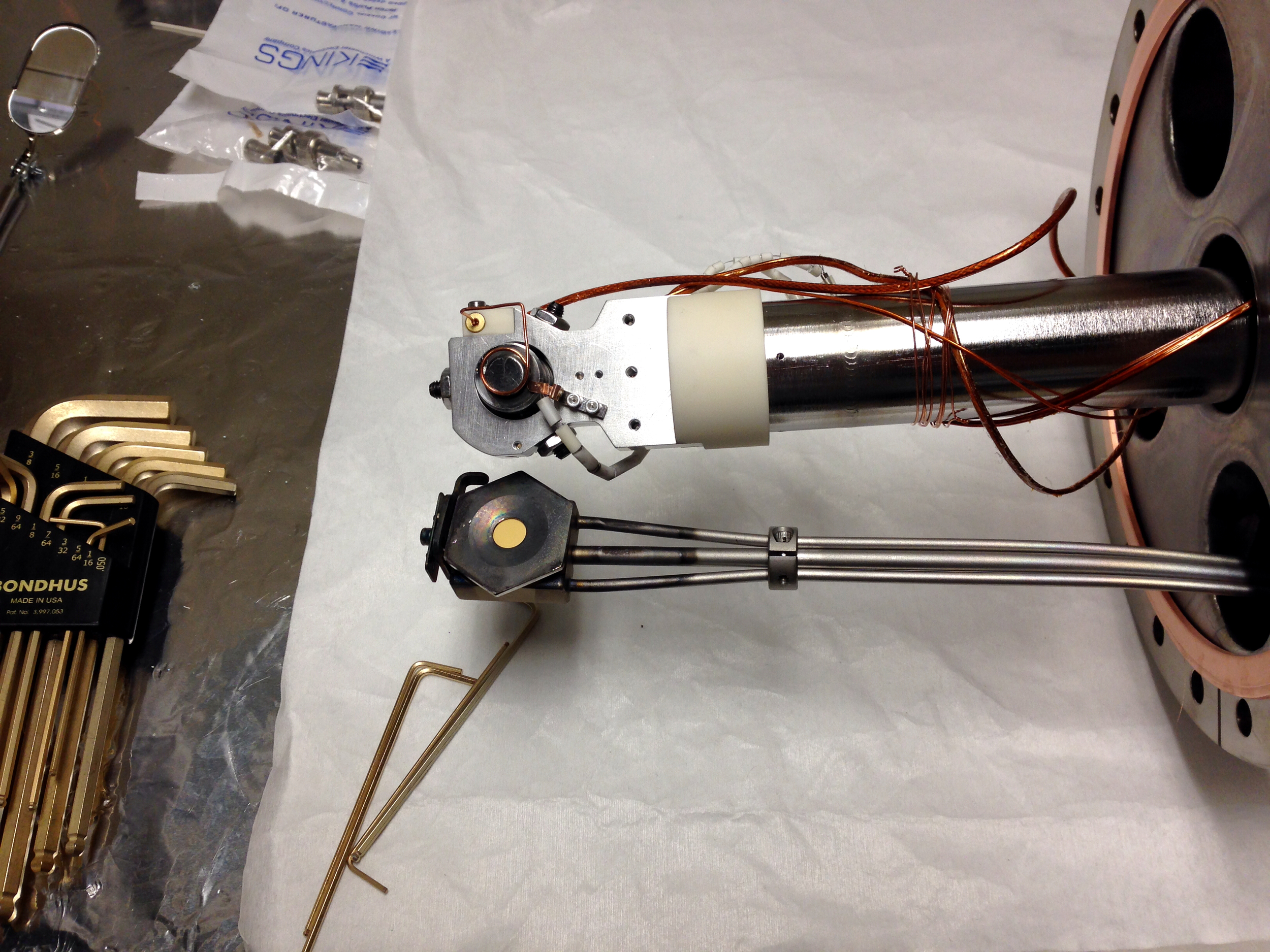

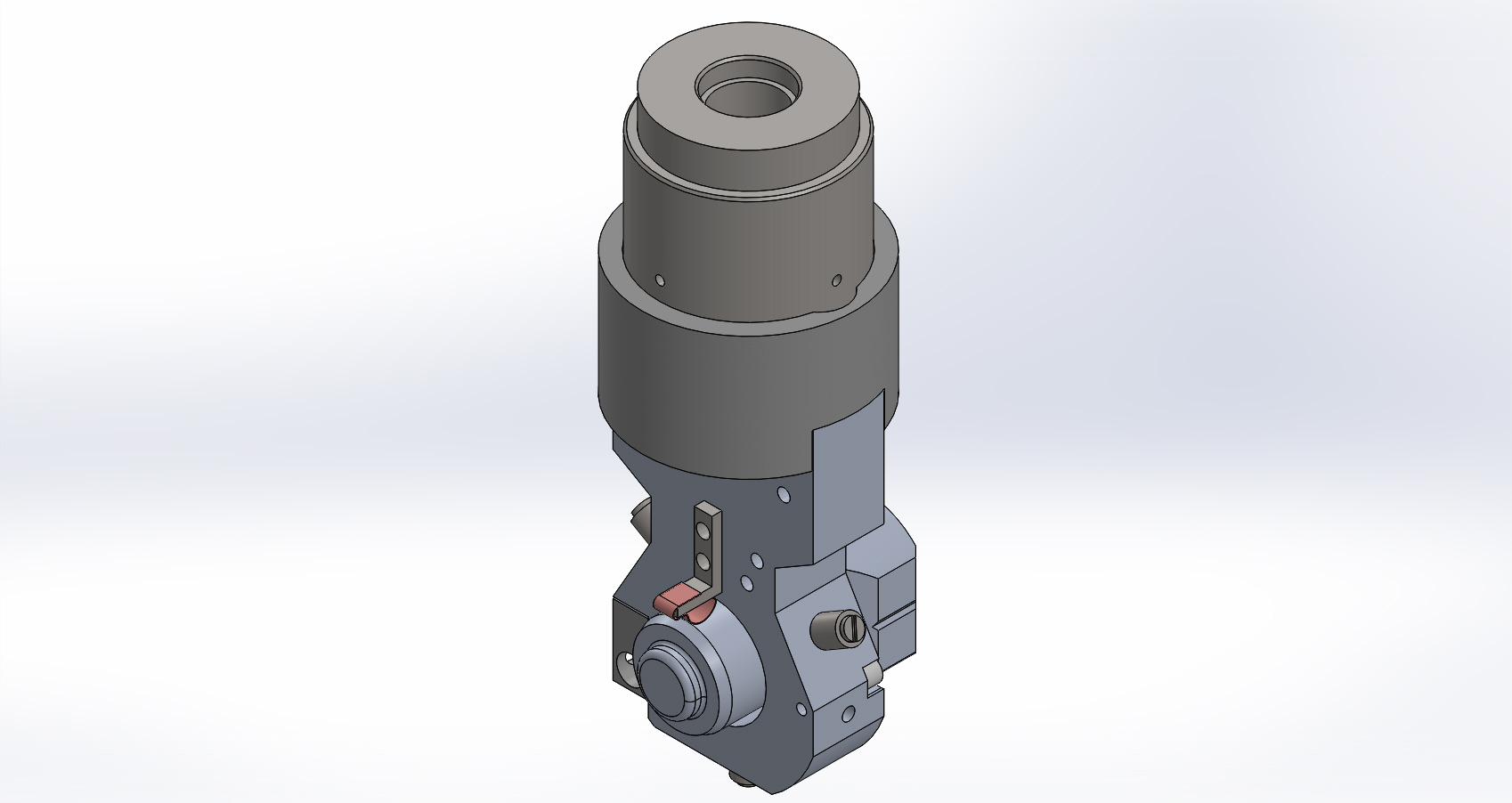

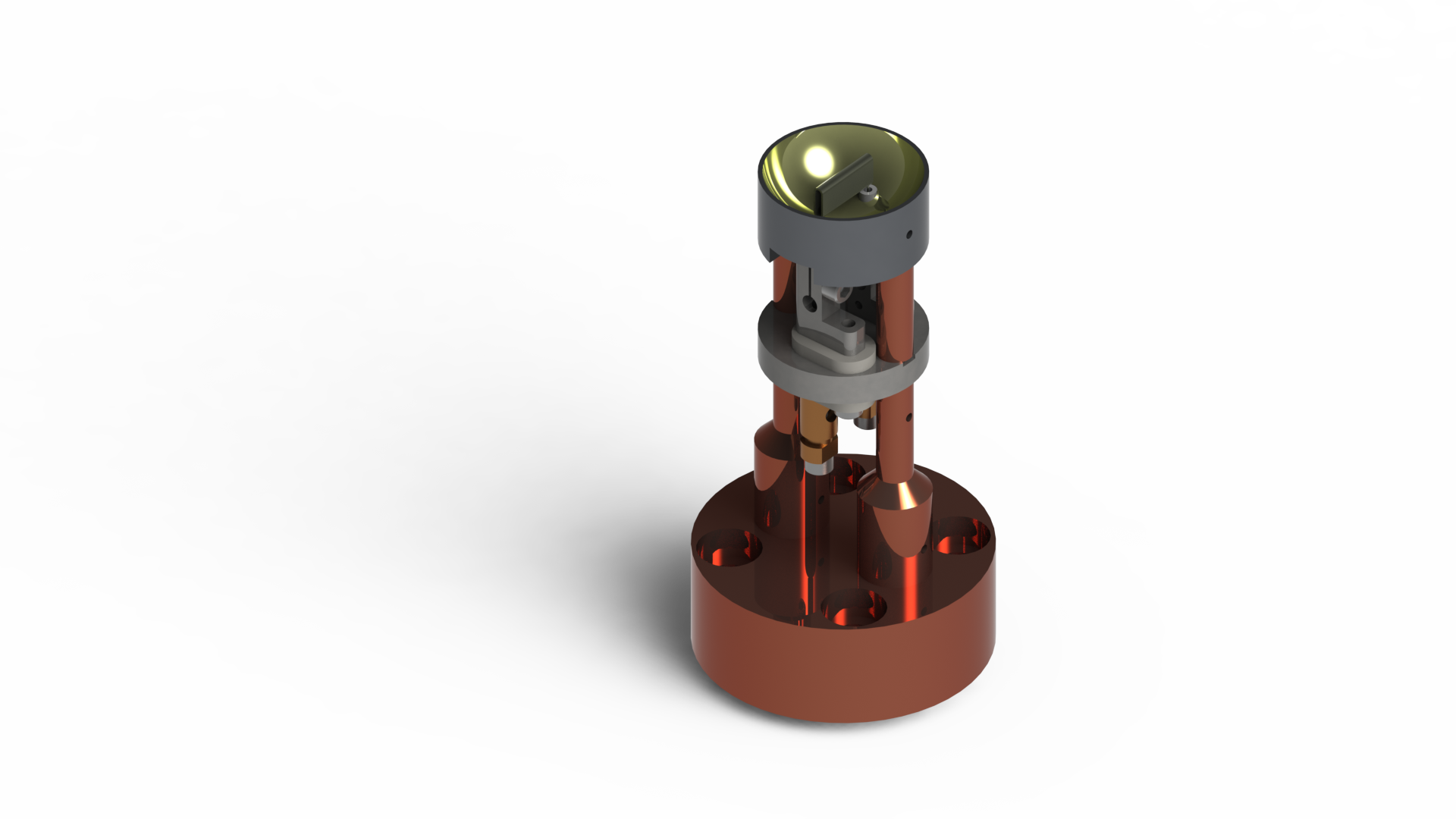

This is accomplished with an infrared heating system thats inserted into the cathode plug and active water cooling on both the cathode holder and the heater mounting. This heater design is unique in that it is much smaller than normally used, and instead of having a highly variable, hand wound filament uses a standard one from a 150W 12V halogen light bulb instead. This means that the system doesn't need to be calibrated every time a filament burns out, and saves a fair amount of money - the halogen bulb costs less than $5 and takes 10 minutes to install vs. having somebody spend several hours hand winding one. Additionally, the reflector directs IR light that would normally be lost back to the heated face giving greater efficiency.

A type K thermocouple is mounted on the cathode holder and contacts the face near the coated surface allowing for accurate temperature monitoring and PID heating control. Typically these types of systems have been pre-calibrated and manually controlled based off of knowing that a giving current results in a certain temperature and allowing the system to slowly come up to temperature over time. The PID control means that the system can come up to temperature very quickly.

A bias ring is mounted to the front of the coating assembly for real-time photocurrent measurements during coating. The mount is electrically isolated and the wiring is shielded such that leakage current is approximately 0.5pA.

The system is bakable to 200C and UHV compatible to 2x10-10 Torr.

Thermal analysis was performed using Solidworks Simulation Pro.